We recently finished one of our most lavish, challenging, and rewarding installs for a brand new building in midtown NYC. The client was asking about holiday party decorations, but this wasn’t a normal party and it wasn’t a normal company. What follows is a step-by-step behind-the-scenes look at how we worked with their team and brought their vision to life in less than a month.

1: THE REQUEST

First off, they wanted a Christmas tree that was absolutely stuffed with handmade origami models. The inspiration came from the Origami tree that the Origami Association of America decorates every year at the Natural History Museum. That tree usually requires upwards of 1,000 models sent in from origami folders from all across the United States and beyond. The client also wanted a unique origami tree skirt around the base of the tree to really tie everything together.

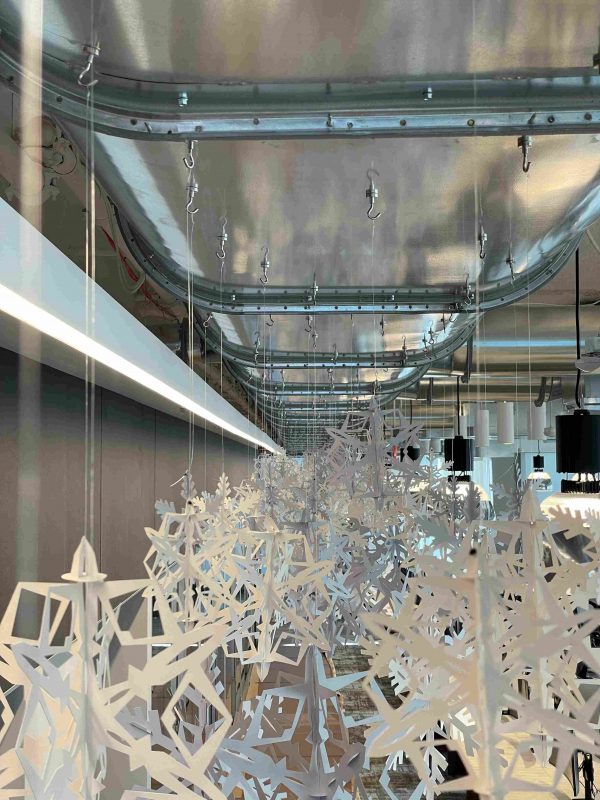

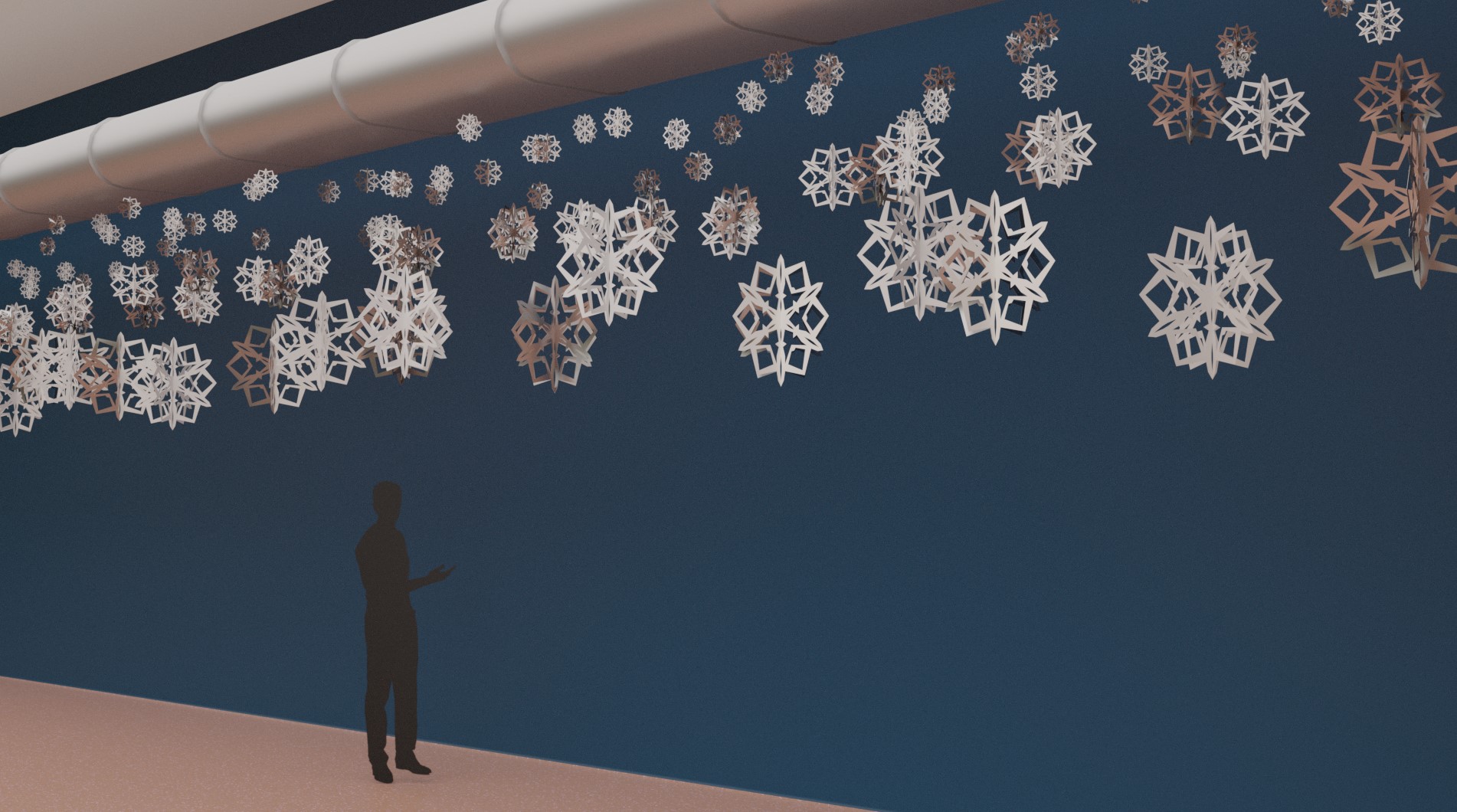

And that was just the first part of the vision. They also wanted to inundate their ceiling with paper snowflakes to create a winter wonderland look. So the mission was to create the models and also figure out how best to hang them. Senior artist Frank Ling visited the space and took some photos of the location to see how best to proceed.

2: DESIGN & REVISIONS

Now as amazing as the Museum Origami tree is, less than a month is simply not enough time to hand make all of the complex models needed, so we worked with the client and chose an array of about 12 different origami creatures and set about making over 300 of them. From there we designed a brand new paper snowflake that we could create using a drag-knife CNC machine to fill out the rest of the branches. After several back-and-forths, we decided on 650 total models for the tree.

The snowflake ornament

For the snowflakes on the ceiling though, we needed to be a little more creative. We couldn’t drill into the new ceiling as it was a fire-retardant foam material, and we didn’t want to have to create a new netting structure, so we went with magnets. 600 of them to be exact. They would attach nicely to the metal ductwork and would then make it a lot easier to reposition and take off as well. After his visit Frank got to work on the 3D computer renders of the space and models and here is how to ended up.

3: INSTALLATION

Over the course of the next 3 weeks, the Taro’s Origami team created thousands handmade of items for this project and coordinated the installation in the highrise. The full installation took place over 3 days and countless amounts of moving ladders around. Slowly though, the snowflakes began to populate the space and the tree took shape.

4: FINAL DISPLAY

Eventually everything ended up in the right place and after a few hours of minor tweaks to make it all perfect- here is the result from this one-of-a-kind experience